WJE PROJECTS

Port of Houston Corrosion Management

CLIENT |

Port of Houston Authority (PHA) |

LOCATION |

Houston, TX |

Program Development and Trial Implementation

PHA initially engaged WJE to develop and implement the Facility Inspection and Condition Assessment Program (FICAP), which assists PHA with asset management by providing structural and functional condition ratings for their maritime assets. Because FICAP is based solely on visual inspection and does not include corrosion protection systems, we were further retained to develop a corrosion management (CM) program as a supplement to FICAP. Corrosion protection is especially important, given the exposure to the harsh marine environment.

BACKGROUND

Owned and operated by the PHA, Port Houston is a 25-mile-long complex of more than 150 private and public industrial terminals along the 52-mile-long Houston Ship Channel.

PHA’s maritime assets consist of cargo wharves, barge landing areas, small boat docks (fireboats and tour boats), bulkheads (unassociated with docks), protected and unprotected shorelines, and one vehicular bridge. Some of these assets range in age from just a few years to more than 100 years old and accordingly have been constructed with a wide range of structural systems and materials.

SOLUTION

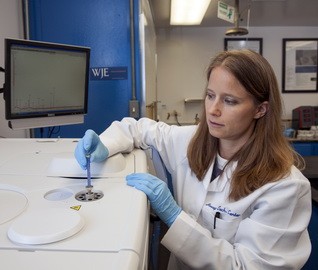

The CM program outlines the process, procedures, and requirements for conducting corrosion inspections and condition assessments of corrosion protection components, including a manual and training course to support engineers, inspectors, and facility managers in its application. The program characterizes the current condition and expected future performance of corrosion protection elements and corresponding base metals using prescribed inspection and condition assessment procedures. The corrosion protection systems include impressed current cathodic protection systems, galvanic or sacrificial cathodic protection systems, metalizing, and other surface protection systems, such as coatings and wraps.

To test the initial development and condition rating system used in the program, WJE performed inspection and condition assessments of three wharfs, including impressed current cathodic protection systems, protective coatings, and base metal elements. Field measurements involved corrosion potential surveys, current readings, coating thickness and adhesion testing, and thickness measurements of metals. Through the implementation of the CM program, a clearer picture of the conditions and performance of existing corrosion protection systems can be obtained to extend the service life of the Port’s maritime assets. Additionally, this program will help PHA make more informed resource allocations for maintenance and rehabilitation planning, ensuring the expected corrosion protection.