Experience

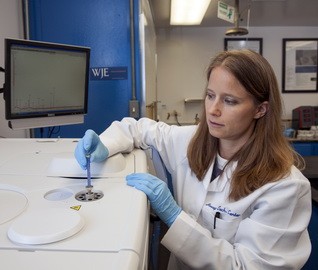

David Schmit is a metallurgical engineer who has worked in the laboratory and in the field on hundreds of projects across numerous industries, including oil and gas, manufacturing, construction, processing, structural, and architectural. Mr. Schmit is focused on failure analysis relating to fracture, corrosion, misuse, and design flaws and has developed extensive knowledge of laboratory material testing and examination techniques.

REPRESENTATIVE PROJECTS

Failure/Damage Investigations

- Hydraulic Tube Leak - IL: Failure analysis and metallurgical evaluations of longitudinal split that occurred after several minutes of service life

- Fire Sprinkler Weld Leak - TX: Metallurgical examination of weld leaks that had occurred in more than thirty Uni-Let fitting welds

- Overhead Condenser Tube Leak - TX: Failure analysis of corroded tubing that failed after four months of service life

- Ruptured U-Bend Pipe - IN: Examination of a hydrotreater feed heater pipe that had ruptured due to high temperature sulfidation and high localized stresses due to excessive wall loss

- Brass Faucet Assembly Valve Fracture - TX: Failure investigation regarding duplex brass valves that had fractured due to stress corrosion cracking

- Bridge Girder Fracture - IL: Metallurgical examination of steel bridge girder that had fractured due to fatigue

- High-Strength Bolt Fracture - IL: Metallurgical examination of structural bolt that had fractured in service due to hydrogen-assisted cracking and work hardening

- Elbow Pipe Leak - IN: Assessment of leaking vacuum lube oil pipe that exhibited erosion-corrosion grooving along intrados of elbow

- Brass Hot/Cold Mixer Fracture - TX: Failure analysis of duplex brass fitting that failed due to stress corrosion cracking after several months in potable water

- Reformer Tube Rupture - WY: Metallurgical examination of ruptured tube that had experienced accelerated creep due to localized hot zones

Material Selection

- Dehumidification Unit Verification - IL: Assessment of component materials after wrong unit was installed constructed of incorrect materials

Corrosion Assessment and Investigation

- Corrosion Rate Testing - IL: Linear polarization resistance measurements using ASTM G5 to determine the corrosion rate of several alloys in a process solution

- Anodized Aluminum Mullion Staining - AL: Determination of the cause of staining and corrosion of aluminum mullions during construction of new building

- Domestic Water Line Leak - PA: Assessment of underground copper piping due to corrosion from the soil side

- Hotel Balcony Bracket Corrosion - FL: Examination of corrosion to 316H stainless steel brackets

- Metro Station Structural Corrosion - Washington, DC: Consulting services on corrosion to stainless steel structural members exposed to an urban environment

Laboratory Testing

- Anodized Aluminum Coating Testing - IL: ASTM B137, B487, and B680 testing to assess quality of anodic coating applied to anodized aluminum snap covers after coating had discolored

- Weldability Testing of Historic Steels - Various Locations: Composition and metallographic examination to determine weldability of historical steels for repair and rehabilitation

- Metallurgical Testing - Projects involving fractography, hardness testing, metallography and chemical analysis

- Corrosion Deposit Analysis - Projects involving the characterization and analysis of corrosion products

Education

University of Illinois at Urbana-Champaign

Bachelor of Science, Materials Science and Engineering, 2018

RELATED INFORMATION

-

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center -

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE provides corrosion assessment services for a wide variety of structures, piping systems,... MORE >Services | Corrosion Assessment

WJE provides corrosion assessment services for a wide variety of structures, piping systems,... MORE >Services | Corrosion Assessment -

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing