Experience

Dr. Damon Panahi specializes in materials science, with specific expertise in physical metallurgy, material characterization, and microstructural-property relationships of metals. He has extensive experience in product development, industrialization, process optimization, and failure mode and effects analysis (process and design FMEA) of engineering materials.

Dr. Panahi also has experience in engineered component compliance with relevant specifications, codes, standards, regulations, and fitness for service. He has applied his expertise to all types of materials investigations in different industries such as automotive structures, building structures, bridges, locomotive components, power generation, and oil and gas pipes.

Dr. Panahi’s project work includes conducting failure investigations, root cause analyses, and risk assessments for clients in the steel manufacturing industry, power generation, oil and gas, aviation, and consumer products safety industries. He led multiple projects on the design and industrialization of advanced high-strength steels for the automotive industry. Dr. Panahi’s focus areas were fundamental metallurgical investigations into the processing-microstructure-property relationship of complex steel chemistries to improve cold formability, surface quality, weldability, and robustness of new high-strength steels for automotive structural components. Under his leadership, several third-generation steels were developed for major automotive manufacturers through collaboration with different steel production facilities worldwide. Dr. Panahi’s fundamental research led to the development of an atomistic, physically-based model for accurately predicting the transformation of austenite to ferrite in steels.

As a domain expert in materials science, he uses his data science knowledge to bridge the two disciplines and accelerate new material development, optimization, and characterization processes through data management, and machine learning techniques.

Dr. Panahi is the author of several US and international patents, book chapters, and peer-reviewed journal papers. He has delivered presentations at international conferences and instructed undergraduate courses related to metal forming and phase transformations.

REPRESENTATIVE PROJECTS

Rail Components and Track Work

- Locomotive Wheels: Derailment analysis and metallurgical assessment of fractured wheels *

Process Industries/Refinery

- Steel Manufacturing: Design and industrialization of advanced high-strength steels for automotive applications *

- Steel Manufacturing: Failure analysis and metallurgical assessment of fractured components in casting facility *

- Oil and Gas: Supporting litigation regarding mercury contamination and damage in subsurface oil transportation lines from offshore facilities *

Civil Infrastructure

- Assessment of hail damage in rooftop steel structures *

Power Industry

- Hydro-Turbine Facility: Supporting litigation through damage assessment, metallurgical analysis, corrosion analysis, and material degradation evaluation of various components; evaluation of materials and manufacturing methods compliance with relevant specifications, codes, standards, and regulations *

* Indicates with previous firms

Registrations

Professional Engineer in IL

Education

Qazvin International University

Bachelor of Engineering, Industrial Metallurgy, 2003

Iran University of Science and Technology

Master of Applied Science, Design and Selection of Engineering Materials, 2006

McMaster University

Master of Science, Materials Science and Engineering, 2009

Doctor of Philosophy, Materials Science and Engineering, 2013

Northwestern University

Master of Science, Data Science, 2020

RELATED INFORMATION

-

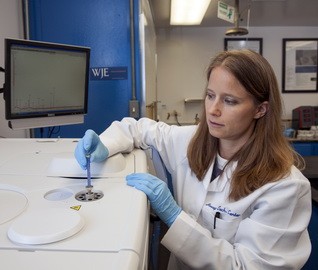

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center -

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE's primary goal of performing a metallurgical failure analysis is to determine the root cause... MORE >Services | Metallurgical Failure Analysis

WJE's primary goal of performing a metallurgical failure analysis is to determine the root cause... MORE >Services | Metallurgical Failure Analysis -

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service